Manufacturing Companies for film capacitor manufacturer in China - Battery-ultracapacitor hybrid energy storage unit – CRE

Manufacturing Companies for film capacitor manufacturer in China - Battery-ultracapacitor hybrid energy storage unit – CRE Detail:

Application

1. Memory backup

2. Energy storage, mainly used for driving motors require a short time operation,

3. Power, higher power demand for a long time operation,

4. Instantaneous power, for applications that requires relatively high current units or peak currents ranging up to several hundreds of amperes even with a short operating time

Electrical performance and safety performance

|

No |

Item |

Test method |

Test requirement |

Remark |

|

1 |

Standard charging mode | At room temperature, the product is charged at a constant current of 1C. When the product voltage reaches the charging limit voltage of 16V, the product is charged at constant voltage until the charging current is less than 250mA. |

/ |

/ |

|

2 |

Standard discharge mode | At room temperature, the discharge will be stopped when the product voltage reaches the discharge limit voltage of 9V. |

/ |

/ |

|

3 |

Rated capacitance |

1. The product is charged according to the standard charging method. |

The product capacity shall be no less than 60000F |

/ |

| 2. Stay 10min | ||||

| 3. The product discharges according to the standard discharge mode. | ||||

|

4 |

Internal resistance |

Ac internal resistance tester tests, precision: 0.01 m Ω |

≦5mΩ |

/ |

|

5 |

Discharge of high temperature |

1. The product is charged according to the standard charging method. |

Discharge capacity should ≥ 95% rated capacity, product appearance without deformation, no burst. |

/ |

| 2. Put the product into the incubator of 60±2℃ for 2H. | ||||

| 3. Discharge the product according to the standard discharge mode, recording discharge capacity. | ||||

| 4. After the discharge, the product will be taken out under normal temperature for 2 hours, and then visual appearance. | ||||

|

6 |

Low-temperature discharge |

1. The product is charged according to the standard charging method. |

discharge capacity≧70% no change on rated capacity, cap appearance, no burst |

/ |

| 2. Put the product into the incubator of -30±2℃ for 2H. | ||||

| 3. Discharge the product according to the standard discharge, recording discharge capacity. | ||||

| 4. After the discharge, the product will be taken out under normal temperature for 2 hours, and then visual appearance. | ||||

|

7 |

Cycle life |

1. The product is charged according to the standard charging method. |

No less than 20,000 cycles |

/ |

| 2. Stay 10min. | ||||

| 3. The product discharges according to the standard discharge mode. | ||||

| 4. Charge and discharge according to the above charging and discharging method for 20,000 cycles, until the discharge capacity is less than 80% of the initial capacity, the cycle is stopped. | ||||

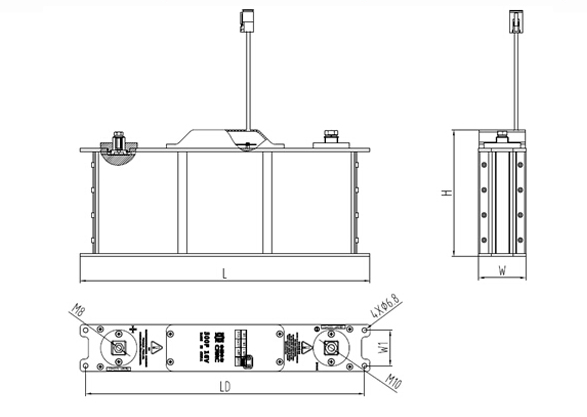

Outline drawing

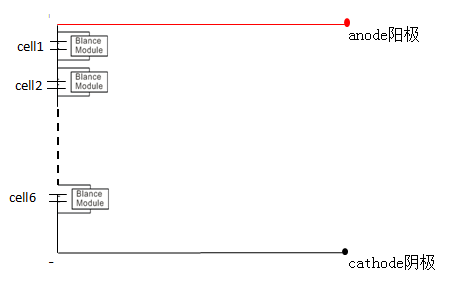

Circuit schematic diagram

Attention

1. The charging current shall not exceed the maximum charging current of this specification. Charging with a current value higher than the recommended value may cause problems in charging and discharging performance, mechanical performance, safety performance, etc. of the capacitor, resulting in heating or leakage.

2. The charging voltage shall not be higher than the rated voltage of 16V specified in this specification.

The charging voltage is higher than the rated voltage value, which may cause problems in the charging and discharging performance, mechanical performance and safety performance of the capacitor, resulting in heat or leakage.

3. The product must be charged at -30~60℃.

4. If the positive and negative poles of the module are connected correctly, reverse charging is strictly prohibited.

5. The discharge current shall not exceed the maximum discharge current specified in the specification.

6. The product must be discharged at -30~60℃.

7. Product voltage is lower than 9V, please do not force discharge;Full charge before use.

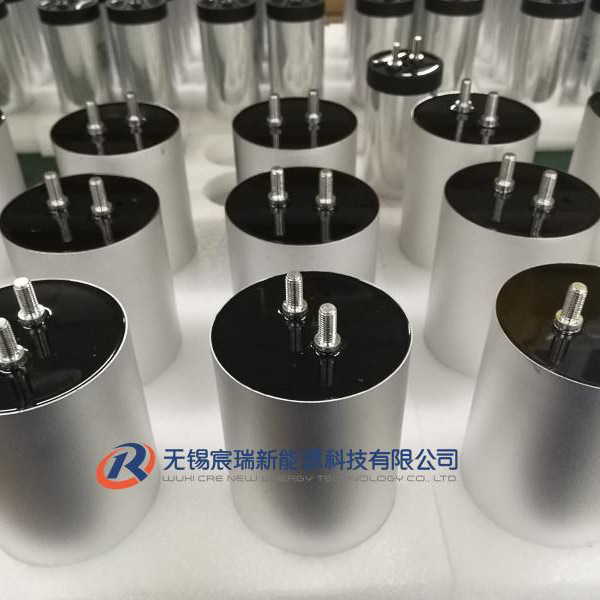

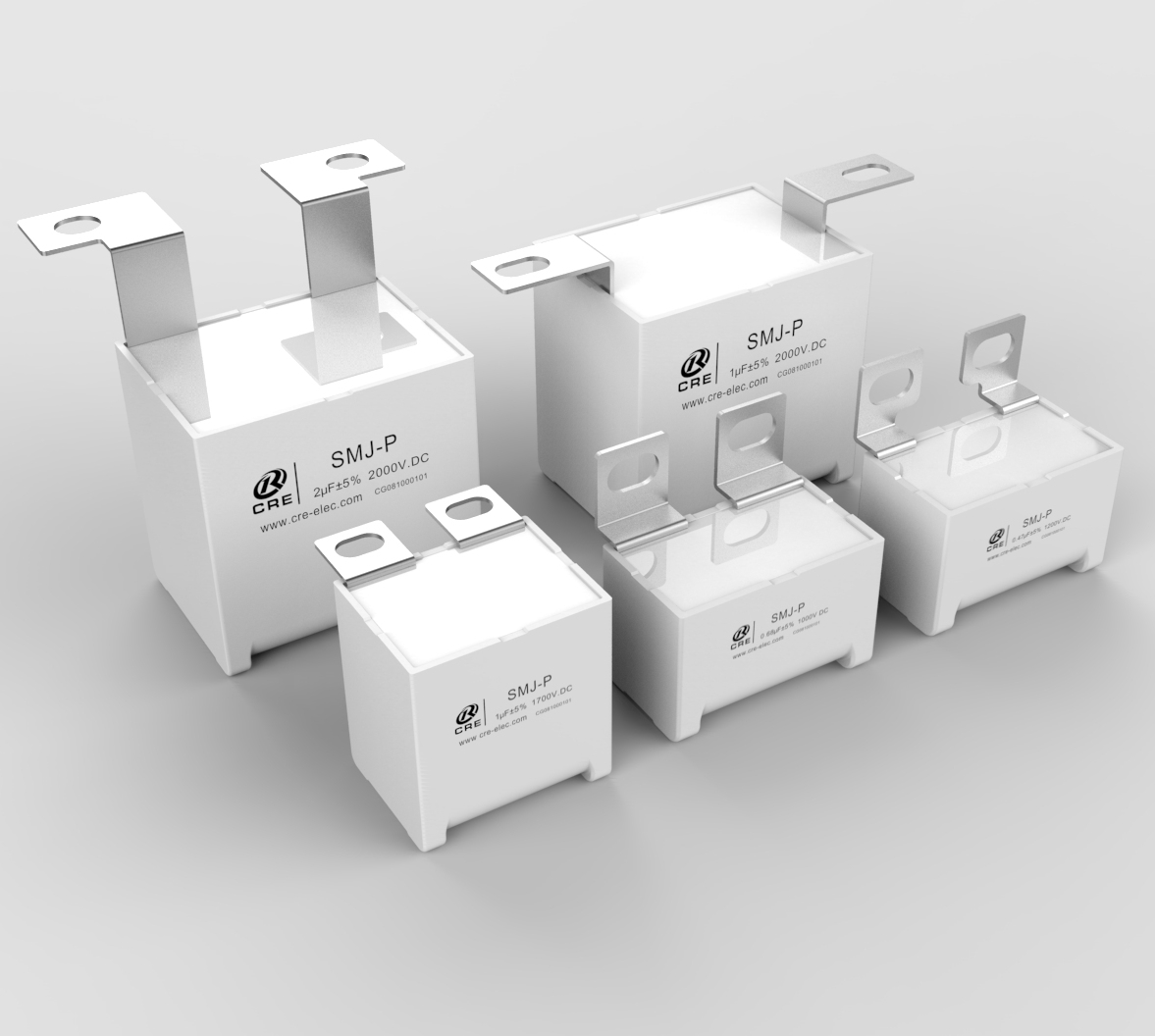

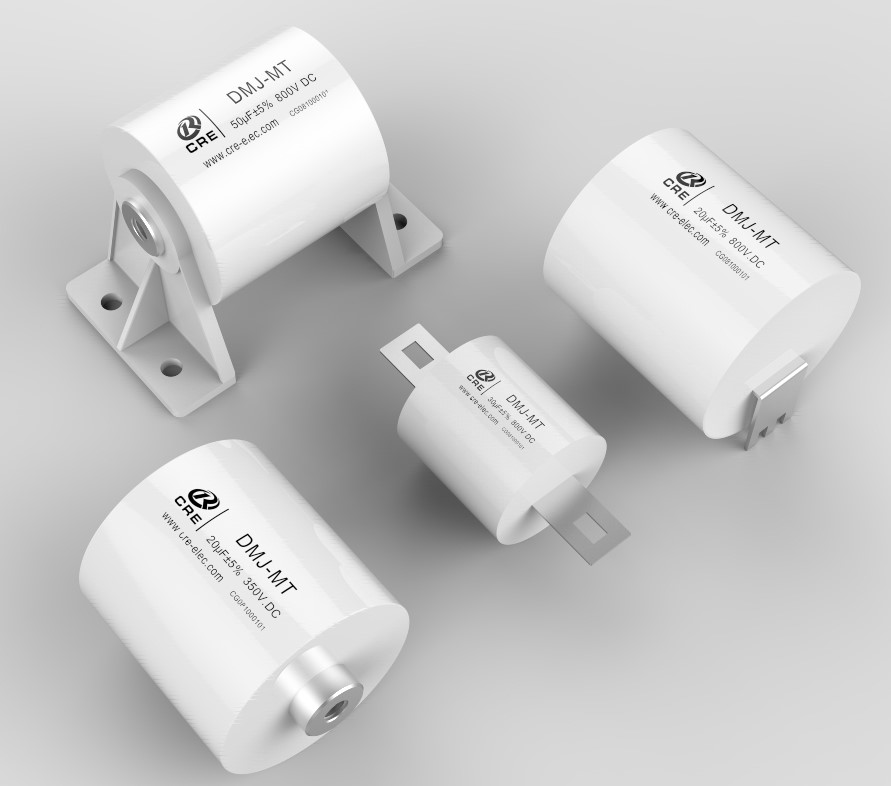

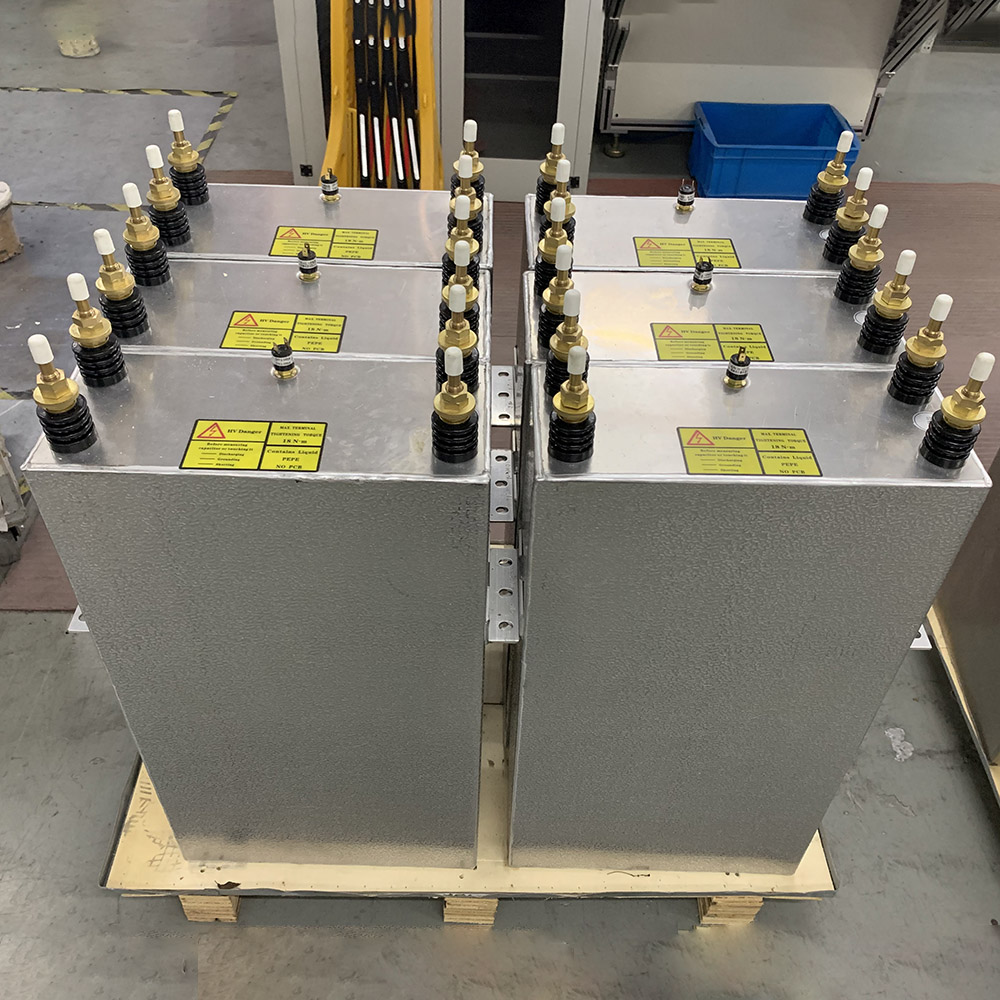

Product detail pictures:

Related Product Guide:

We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for Manufacturing Companies for film capacitor manufacturer in China - Battery-ultracapacitor hybrid energy storage unit – CRE , The product will supply to all over the world, such as: Vietnam, UK, Armenia, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to "create first-class products" as the goal, and strive to provide customers with high quality products, provide high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!