High Performance Capacitors In Automotive Applications - Customized Dry Film Capacitors design for High-Frequency Power Electronics – CRE

High Performance Capacitors In Automotive Applications - Customized Dry Film Capacitors design for High-Frequency Power Electronics – CRE Detail:

Our strengths

1. CRE is continually doing the development to increase energy density, reliability, and efficiency while decreasing size, weight, and cost.

2. As a professional film capacitor designer, we apply film/segmented film materials and techniques to optimize the capacitor performance characteristics for a given application.

3. With years of experience, CRE keeps on developing innovative capacitor solutions for our customers around the world.

Technical data

| Operating temperature range | Max Operating temperature: + 70℃Upper category temperature: +60℃

Lower category temperature: -40℃ |

|

| capacitance range |

100μF~20000μF |

|

| Un/ Rated voltage Un |

600V.DC~4000V.DC |

|

| Capacitance tolerance |

±5%(J);±10%(K) |

|

| Withstand voltage |

Vt-t |

1.5Un DC/60S |

|

Vt-c |

1000+2×Un/√2 (V.AC) 60S(min 3000 V.AC) |

|

| Over Voltage |

1.1Un(30% of on-load-during) |

|

|

1.15Un(30min/day) |

||

|

1.2Un(5min/day) |

||

|

1.3Un(1min/day) |

||

|

1.5Un(100ms every time,1000times during the lifetime) |

||

| Dissipation factor |

tgδ≤0.003 f=100Hz |

|

|

tgδ0≤0.0002 |

||

| ESL |

<150 NH |

|

| Flame retardation |

UL94V-0 |

|

| Maximum altitude |

2000m |

|

| When the altitude is above 2000m to below 5000m, it is necessary to consider the use of a reduced amount.(for each increase of 1000m, the voltage and current will be reduced by 10%) | ||

| Life expectancy |

100000h(Un; Θhotspot ≤70 °C ) |

|

| Reference standard |

IEC 61071 ;IEC 61881; |

|

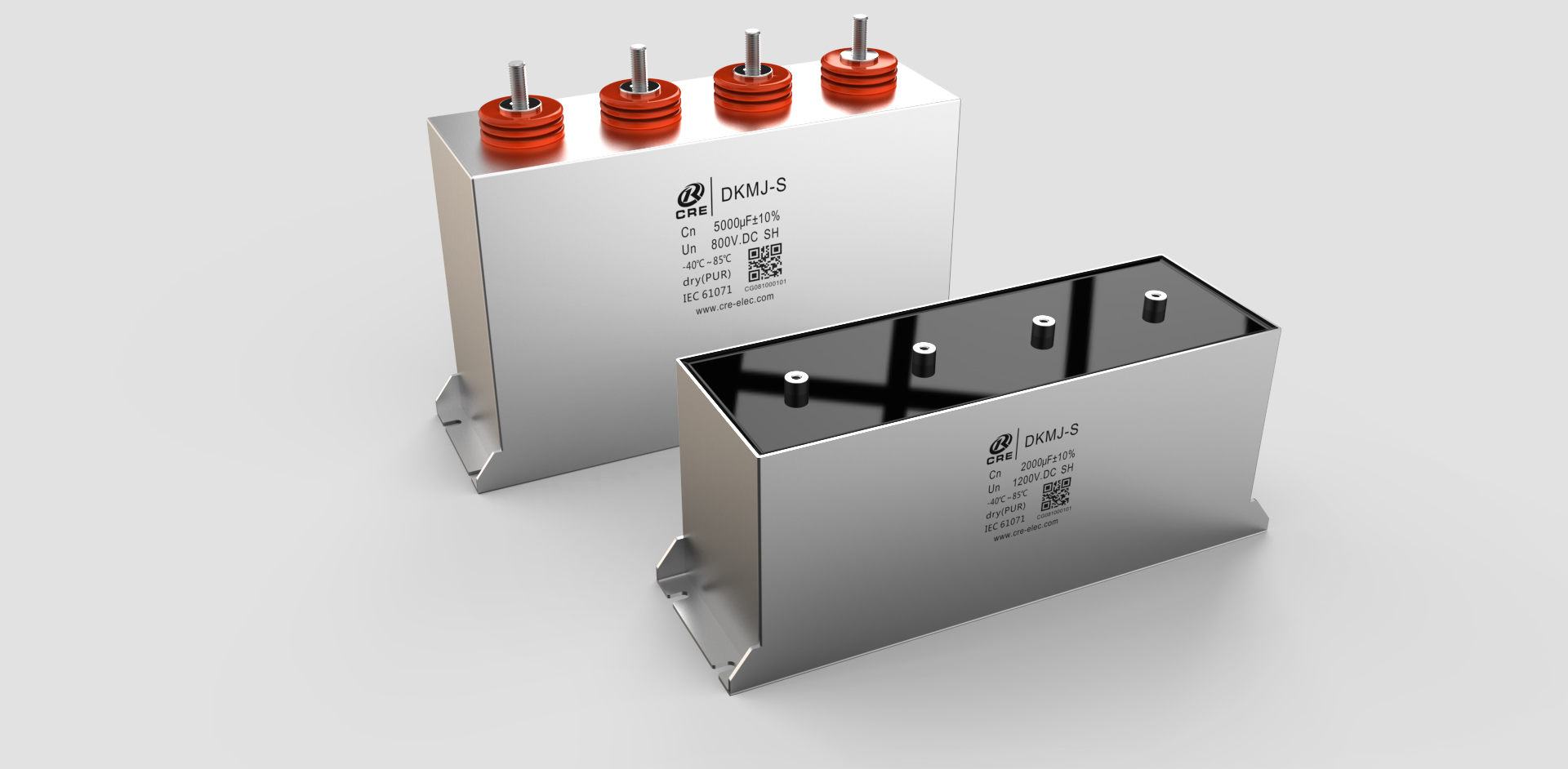

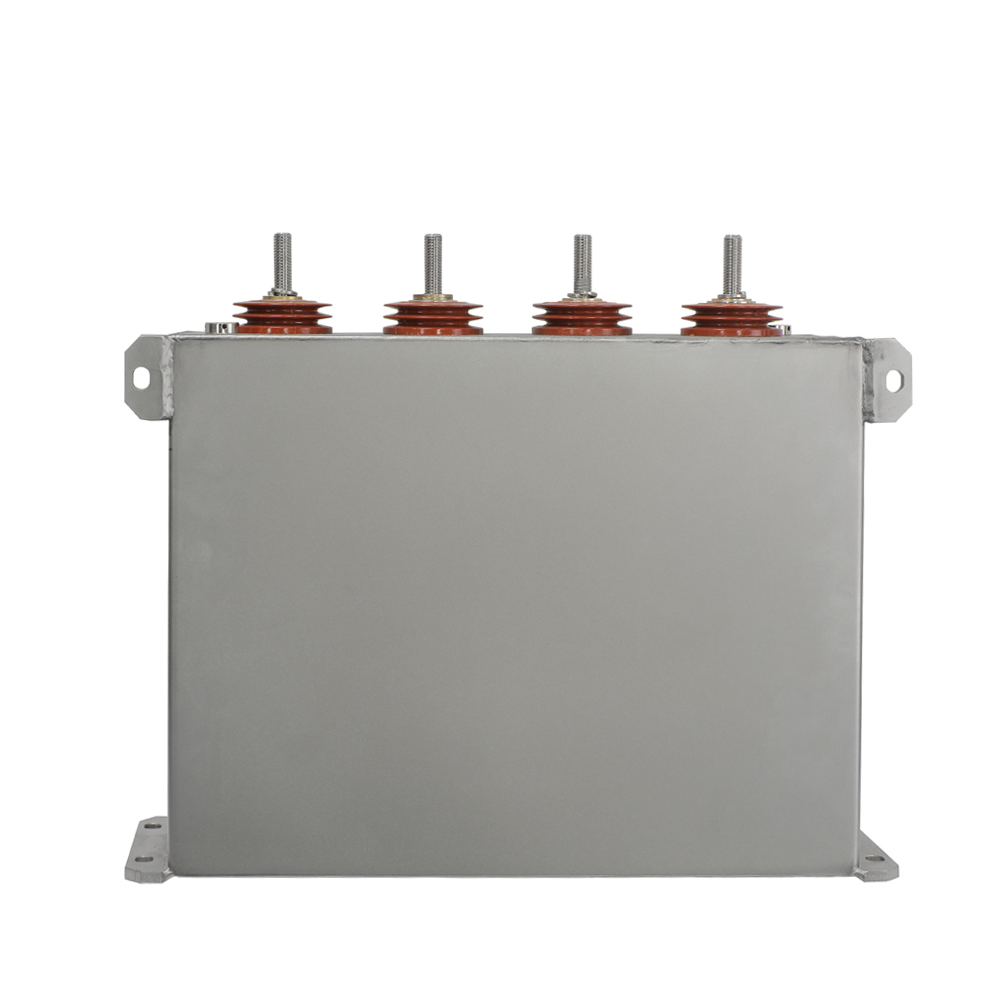

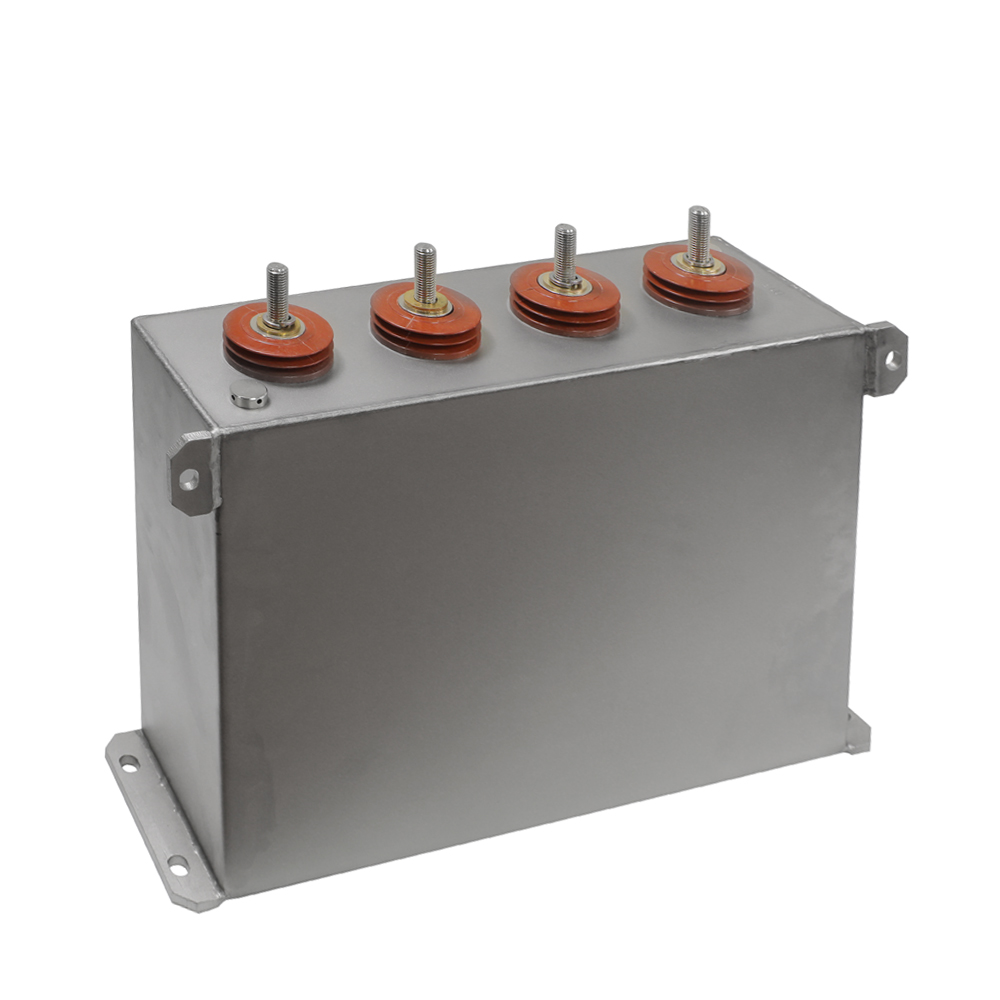

Feature

1. Metal shell encapsulation, dry resin infusion;

2. Copper nut/screw leads, easy installation;

3. Large capacity, customize dimension;

4. Resistance to high voltage, with self-healing ability;

5. High ripple current, high dv / dt withstand capability.

Specification table

| Voltage | Un 800V.DC Us 1200V Ur 200V | ||||||||

| Cn (μF) | W (mm) | T (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms(A)50℃@10KHz | ESR (mΩ) @1KHz | Rth (K/W) | Weight (Kg) |

| 4000 | 340 | 125 | 190 | 5 | 20.0 | 120 | 1.1 | 0.9 | 17.6 |

| 8000 | 340 | 125 | 350 | 4 | 32.0 | 180 | 0.72 | 0.6 | 31.2 |

| 6000 | 420 | 125 | 245 | 5 | 30.0 | 150 | 0.95 | 0.7 | 26.4 |

| 10000 | 420 | 125 | 360 | 4 | 40.0 | 200 | 0.72 | 0.5 | 39.2 |

| 12000 | 420 | 235 | 245 | 4 | 48.0 | 250 | 0.9 | 0.3 | 49.6 |

| 20000 | 420 | 235 | 360 | 3 | 60.0 | 300 | 0.6 | 0.3 | 73.6 |

| Voltage | Un 1200V.DC Us 1800V Ur 300V | ||||||||

| Cn (μF) | W (mm) | T (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms(A)50℃@10KHz | ESR (mΩ) @1KHz | Rth (K/W) | Weight (Kg) |

| 2500 | 340 | 125 | 190 | 8 | 20.0 | 120 | 1.1 | 0.9 | 17.6 |

| 3300 | 340 | 125 | 245 | 8 | 26.4 | 150 | 0.95 | 0.7 | 22.4 |

| 5000 | 420 | 125 | 300 | 7 | 35.0 | 180 | 0.8 | 0.6 | 32.8 |

| 7500 | 420 | 125 | 430 | 5.5 | 41.3 | 200 | 0.66 | 0.6 | 44.8 |

| 5000 | 340 | 235 | 190 | 8 | 40.0 | 200 | 1.1 | 0.3 | 32.8 |

| 10000 | 340 | 235 | 350 | 6 | 60.0 | 250 | 0.8 | 0.3 | 58.4 |

| 5000 | 420 | 235 | 175 | 8 | 40.0 | 200 | 1 | 0.4 | 36 |

| 7500 | 420 | 235 | 245 | 7 | 52.5 | 250 | 0.9 | 0.3 | 49.6 |

| 10000 | 420 | 235 | 300 | 7 | 70.0 | 250 | 0.8 | 0.3 | 61.6 |

| 15000 | 420 | 235 | 430 | 5 | 75.0 | 300 | 0.6 | 0.3 | 84 |

| Voltage | Un 1500V.DC Us 2250V Ur 450V | ||||||||

| Cn (μF) | W (mm) | T (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms(A)50℃@10KHz | ESR (mΩ) @1KHz | Rth (K/W) | Weight (Kg) |

| 1200 | 340 | 125 | 190 | 10 | 12.0 | 120 | 1.1 | 0.9 | 17.6 |

| 3000 | 340 | 125 | 420 | 8 | 24.0 | 180 | 0.66 | 0.7 | 37.6 |

| 2000 | 420 | 125 | 245 | 10 | 20.0 | 150 | 0.95 | 0.7 | 26.4 |

| 4000 | 420 | 125 | 430 | 8 | 32.0 | 200 | 0.66 | 0.6 | 44.8 |

| 5000 | 340 | 235 | 350 | 8 | 40.0 | 250 | 0.8 | 0.3 | 58.4 |

| 4000 | 420 | 235 | 245 | 10 | 40.0 | 250 | 0.9 | 0.3 | 49.6 |

| 8000 | 420 | 235 | 430 | 8 | 64.0 | 300 | 0.6 | 0.3 | 84 |

| Voltage | Un 2000V.DC Us 3000V Ur 600V | ||||||||

| Cn (μF) | W (mm) | T (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms(A)50℃@10KHz | ESR (mΩ) @1KHz | Rth (K/W) | Weight (Kg) |

| 1000 | 340 | 125 | 245 | 12 | 12.0 | 150 | 0.95 | 0.7 | 22.4 |

| 1500 | 340 | 125 | 350 | 10 | 15.0 | 180 | 0.72 | 0.6 | 31.2 |

| 2000 | 420 | 125 | 360 | 10 | 20.0 | 200 | 0.72 | 0.5 | 39.2 |

| 2400 | 420 | 125 | 430 | 9 | 21.6 | 200 | 0.66 | 0.6 | 44.8 |

| 3200 | 340 | 235 | 350 | 10 | 32.0 | 250 | 0.8 | 0.3 | 46.4 |

| 4000 | 420 | 235 | 360 | 10 | 40.0 | 280 | 0.7 | 0.3 | 58.4 |

| 4800 | 420 | 235 | 430 | 9 | 43.2 | 300 | 0.6 | 0.3 | 67.2 |

| Voltage | Un 2200V.DC Us 3300V Ur 600V | ||||||||

| Cn (μF) | W (mm) | T (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms (A)max | ESR (mΩ) | Rth (K/W) | Weight (Kg) |

| 2000 | 420 | 235 | 245 | 12 | 24 | 150 | 0.9 | 0.740740741 | 40 |

| 2750 | 420 | 235 | 300 | 10 | 27.5 | 200 | 0.8 | 0.46875 | 49.6 |

| 3500 | 420 | 235 | 360 | 10 | 35 | 200 | 0.7 | 0.535714286 | 58.4 |

| Voltage | Un 3000V.DC Us 4500V Ur 800V | ||||||||

| Cn (μF) | W (mm) | T (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms (A)max | ESR (mΩ) | Rth (K/W) | Weight (Kg) |

| 1050 | 420 | 235 | 245 | 20 | 21 | 150 | 0.9 | 0.740740741 | 40 |

| 1400 | 420 | 235 | 300 | 15 | 21 | 200 | 0.8 | 0.46875 | 49.6 |

| 1800 | 420 | 235 | 360 | 15 | 27 | 200 | 0.7 | 0.535714286 | 58.4 |

| Voltage | Un 4000V.DC Us 6000V Ur 1000V | ||||||||

| Cn (μF) | W (mm) | T (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms (A)max | ESR (mΩ) | Rth (K/W) | Weight (Kg) |

| 600 | 420 | 235 | 245 | 20 | 12 | 150 | 0.9 | 0.740740741 | 40 |

| 800 | 420 | 235 | 300 | 20 | 16 | 200 | 0.8 | 0.46875 | 49.6 |

| 1000 | 420 | 235 | 360 | 20 | 20 | 200 | 0.7 | 0.535714286 | 58.4 |

| Voltage | Un 2800V.DC Us 4200V Ur 800V | ||||||||

| Cn (μF) | W (mm) | T (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms(A)50℃@10KHz | ESR (mΩ) @1KHz | Rth (K/W) | Weight (Kg) |

| 2×1000 | 560 | 190 | 310 | 20 | 2×20 | 2×350 | 1 | 0.2 | 60 |

| Voltage | Un 3200V.DC Us 4800V Ur 900V | ||||||||

| Cn (μF) | W (mm) | T (mm) | H (mm) | dv/dt (V/μS) | Ip (KA) | Irms(A)50℃@10KHz | ESR (mΩ) @1KHz | Rth (K/W) | Weight (Kg) |

| 2×1200 | 340 | 175 | 950 | 15 | 2×18 | 2×200 | 1.0 | 0.5 | 95 |

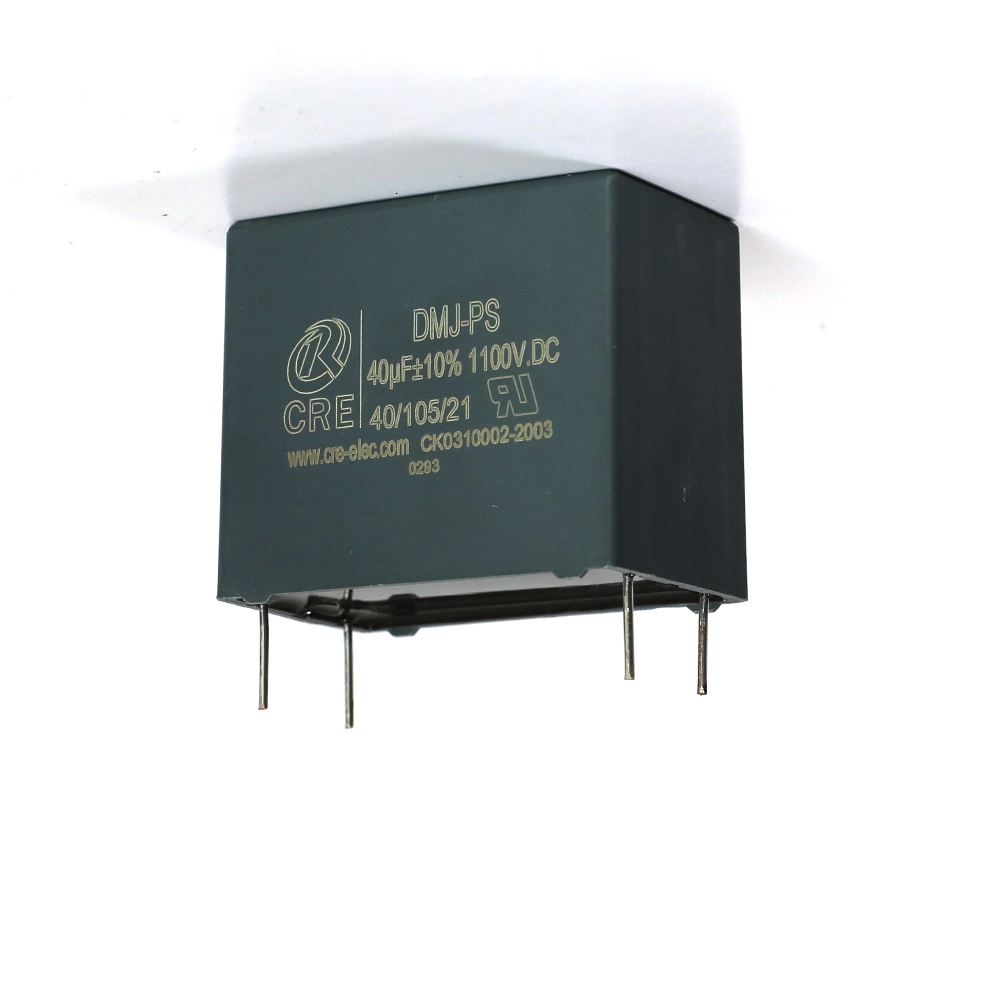

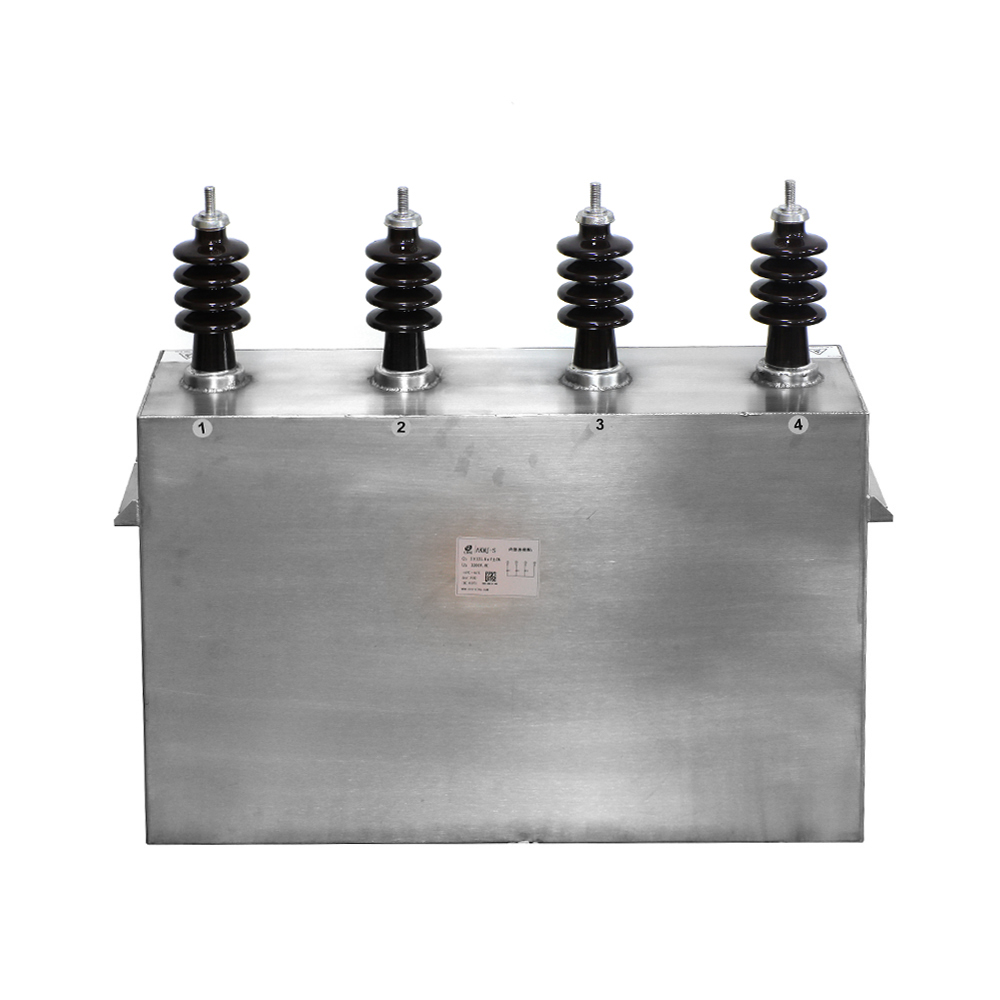

Product detail pictures:

Related Product Guide:

We insist on offering good quality generation with very good business enterprise concept, honest income as well as best and fast assistance. it will bring you not only the premium quality product or service and huge profit, but probably the most significant is usually to occupy the endless market for High Performance Capacitors In Automotive Applications - Customized Dry Film Capacitors design for High-Frequency Power Electronics – CRE , The product will supply to all over the world, such as: Marseille, Nepal, Nigeria, With excellent products, high quality service and sincere attitude of service, we ensure customer satisfaction and help customers create value for mutual benefit and create a win-win situation. Welcome customers all over the world to contact us or visit our company. We will satisfy you with our professional service!

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.