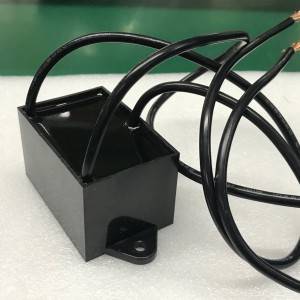

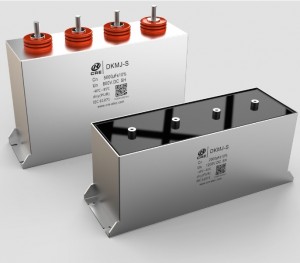

Custom-made Power capacitors used in DC-link circuits

Specification

The performance characteristics of film capacitors vary mainly depending on the dielectric material used as well as the construction technology applied. Some of the most commonly used plastic film dielectrics include polyethylene naphthalate (PEN), polyethylene terephthalate (PET), and polypropylene (PP).

Plastic film capacitors can be broadly categorized into film/foil and metallized film capacitors. The basic structure of a film/foil capacitor consists of two metal foil electrodes and a plastic film dielectric between them. Film/foil capacitors offer high insulation resistance, high pulse handling capability, excellent current carrying capability, and good capacitance stability. Unlike film/foil capacitors, metallized film capacitors use metal-coated plastic films as electrodes. Metallized film capacitors have reduced physical sizes, and offer high volumetric efficiency, good capacitance stability, low dielectric losses, and excellent self-healing properties. Some capacitors are a hybrid of film/foil capacitors and metallized film capacitors and feature characteristics of both types. The self-healing properties of metallized film capacitors make them ideal for a broad spectrum of applications, including long life and benign failure mode circuits.

Self-healing of metallized film capacitors

The plastic film dielectrics that are commonly used in the construction of metallized film capacitors include polypropylene (PP), polyphenylene sulfide (PPS), polyester, and metalized paper (MP). These dielectric materials have different self-healing capabilities.

When breakdown occurs in a metallized film capacitor, arcing causes the thin metal layer around the fault area to vaporize. This vaporization process removes the conductive metal layer in the area around the flaw. Since the conductive material is removed, a short circuit cannot occur between the plates. This prevents failure of the component.

The self-healing capability of a metallized film capacitor depends on many factors including the properties of the dielectric material and the thickness of the metal layer. The vaporization process requires adequate supply of oxygen and dielectric materials with high surface oxygen content have good self-healing properties. Some of the plastic film dielectrics that have good self-healing characteristics include polypropylene, polyester and polycarbonate. On the other hand, plastic film dielectrics with low surface oxygen content have poor self-healing characteristics. Polyphenylene sulfide (PPS) is one such dielectric material.

Apart from enhancing reliability, the self-healing capability of metallized film capacitors helps to enhance their operational life. However, self-healings cause reduction of the metallized electrode area over time.

In applications, some of the conditions that can accelerate failure of a component include high temperatures, high voltages, lightning, high humidity, and electromagnetic interference (EMI).

Apart from good self-healing properties, metallized polyester film capacitors also have a high dielectric constant, good temperature stability, high dielectric strength, and excellent volumetric efficiency. These characteristics make these capacitors ideal for general purpose applications. Metallized polyester capacitors are widely used for DC applications such as blocking, bypassing, decoupling, and noise suppression.

Metallized polypropylene capacitors offer high insulation resistance, low dielectric absorption, low dielectric losses, high dielectric strength, and long term stability. These space-efficient components are widely used in mains-attached applications such as filter circuits, lighting ballasts, and snubber circuits. Double metallized polypropylene film capacitors can withstand high voltage and high-pulse loads, and they are suitable for applications with a high likelihood of steep pulses. These capacitors are commonly used in motor controllers, snubbers, switch mode power supplies, and monitors.

Conclusion

The reliability and operational life of capacitors significantly depend on their self-healing characteristics. Passive components with good self-healing characteristics are more reliable and offer a longer operational life. The good self-healing characteristics of metallized film capacitors enhance their robustness and make them suitable for many applications. In addition, these robust components fail open-circuit, and this makes them ideal for applications that demand components with a safer failure mode.

On the flip side, the self-healing property of metallized film capacitors causes the loss factor to increase and the total capacitance to drop. Apart from good self-healing properties, most metallized film capacitors also offer high breakdown strength and high volumetric efficiency.

For more film capacitor details, please download CRE catalog.